Dyeing Guide

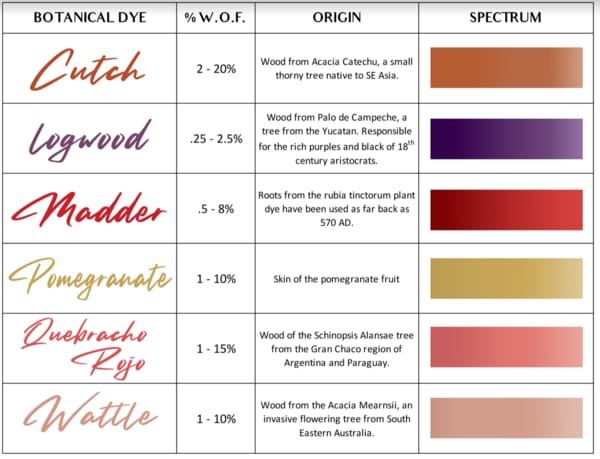

Want to know the facts behind our extracts? Find more info here.

Fabric Funhouse is proud to introduce another eco-conscious product line: a collection of natural dye extracts, curated exclusively for plant-based fibers. Although there are natural dye extracts from insects and mollusks, and animal fiber textiles, we remain animal friendly and botanical. Natural dye has been used throughout history, as dyers relied on color sources from the earth. Many plants will produce color, but not all plants produce indiscriminate dyes, or colors that have stood the test of time. These botanical dye extracts, from all over the world, have a story to tell. Since the introduction of synthetic dyes in 1856, the art of natural dyeing has become nearly irrelevant. As history tells, the development of synthetic dyes was not without its environmental repercussions. We invite makers to embark on a natural dye revival.

Fabric Funhouse PFD Fabrics (Prepared for Dyeing) are free of additives commonly used in the textile industry. These oils, waxes or substances prevent the dye from bonding to the fabrics. Because of these additives, non-PFD fabrics will require an extra process called scouring. Scouring is a high heat washing of the fabrics prior to dyeing. Laundered fabric will make its way to the mordanting process. Mordants are metal salts, the quality and quantity of which will affect the final product. Since cellulose fibers do not have a strong affinity for natural dyes, a mordant is needed to fix the dye in the fibers.

Tap water is generally perfect but metals and pH can affect the result. Iron is most problematic for dyers, unless you are trying to achieve greys or black. If your water has iron, it will react with the fabric and sadden, or grey-out, the result. Luckily, there is an easy way to test it. A dash of Gallo Tannin and water with iron will turn the water grey. If you find high iron levels in your water source, distilled water is a perfect alternative.

TERMINOLOGY:

- pH: A measure of acidity or alkalinity of water-soluble substances (pH stands for ‘potential of Hydrogen’). A pH value is a number from 1 to 14, 1 being the most acidic and 14 being the most alkaline, with 7 as the middle (neutral) point.

- PFD: Prepared for dyeing

- W.O.F.: While normally an acronym for width of fabric in the sewing world, when referring to the dyeing process it stands for Weight Of Fabric.

- Scour: Removing natural and manufactural residue by high heat washing of the fabrics to be dyed.

- Mordant: The term mordant comes from the Latin mordere, "to bite". In the past, it was thought that a mordant helped the dye bite onto the fiber so that it would hold fast during washing. A mordant is a substance used to set (bind) dyes on fabrics by forming a coordination complex with the dye, which then attaches to the fabric (or tissue). It may be used for dyeing fabrics or for intensifying stains in cell or tissue preparations.

- Wet Out: to wetthoroughly or to make textiles more absorbent by treating with a wetting agent prior to dyeing, in our case this agent is simply water. Even wetness throughout fabric that can be achieved in a 5-gallon bucket of water. You may add a little neutral detergent to cut water tension to curb fabric from floating to the top. Wet out is also sometimes used to refer to mixing materials with hot water to make a solution.

- Chalk Bath: In some cultures, this is known as “dunging” as cowdung is used instead of Calcium Carbonate. Note: Once this step is completed, cellulose fibers can be fully dried and stored before dyeing, though they will need to be wetted out again before moving on to that step.

- Stop Bath: a bath for stopping the action of a preceding bath by neutralizing any of its chemical still present on the fibers. Placing fabric in a stop bath, the dye present in the fibers will stop processing to a darker/deeper color.

SAFETY ALERT - Never use food preparation, tools, or equipment for dyeing and have designated, marked equipment solely for this use.

Protective Equipment - Face mask, gloves, protective glasses, and long sleeves. Only use non-reactive materials such as plastic, glass, or stainless steel (other metals will affect the color result).

Equipment - Large, stainless steel pot(s), 3 non-reactive mixing bowls, whisk, burner or hot plate for outdoor mordanting, food scale (grams), glass beaker or measuring cup for calculating weights, a thermometer, and 3 - 5-gallon buckets (1 for Mordanting, 1 for Chalk Bath, and 1 for Wetting out Fabrics). Ensure you have lids for your buckets if you wish to store the Mordant or Chalk Bath for later use.

Materials - pH-neutral detergent (we recommend a liquid version to make the process a little easier), Soda Ash, Aluminum Acetate, Calcium Carbonate, Botanical Dye Extract, Color Modifiers (optional).

Preparing Textiles for Immersion Dyeing

Each fiber has a pH where it is strongest. Cellulose fibers are tolerant of acidic and alkaline conditions but happiest at a neutral pH. Soaps are not suitable for preparing cellulose fiber because the can react to minerals in the water to create fatty substances that will make the fiber repel the mordants and dyes. Natural detergents that include yucca root or soapwort (Saponaria) are poisonous to fish and insects and are not more environmentally friendly than detergents with synthetic ingredients. Preferred detergents are PH-neutral and eco-conscious (Ex. Orvus Paste, Synthropol, neutral pH dishwashing liquids, All Free and Gentle detergents, Not Free and Clear). The neutral pH will ensure that the next steps won’t be influenced by pH in the mordanting and dyeing process, even if rinsing is not thorough.

All the calculations are based on the weight of the fabric in grams. Dyers use the acronym w.o.f. for this but we do not want to confuse that with sewing width of fabric, so it may sound repetitive. You can find the weight per yard in each of our fabric listing descriptions. Ex. If your fabric weighs 100g and you need 2% of an extract, you will need 2g of extract. We have designed a calculator to help you with this so don’t let the math or metric system discourage you! Note: The mass of these extracts and substances do not have the same volume so refrain from converting grams to cups/tablespoons. Stick with weight and you’ll do great!

STEP 1 - SCOURING

Using our Fabrics? Just wash in washing machine with pH-Neutral Laundry Detergent and ¼ - ½ cup of Soda Ash per load on Hot. SKIP to Step 2 - Mordanting.

Non-PFD Fabrics: Without scouring, or removing natural and manufactural residue, the mordant and dye will not penetrate the fibers.

Materials: pH-Neutral Detergent + Soda Ash, a non-reactive bowl and whisk to dissolve Soda Ash, large stainless-steel pot with plenty of room for fabric to move freely, heat source, and a thermometer.

pH Neutral Detergent – 5.5% weight of the fabric

Soda Ash - 2% weight of the fabric

- Wet out your fibers.

- Put Soda Ash into a non-reactive bowl with a little cool water, then gradually add boiling water to dissolve into a soda ash solution, whisk until dissolved. If you are not using a liquid detergent, do this same process to dissolve it as well.

- Fill dye pot with enough room temperature water that the fibers will be able to move freely and place on heating source. Add the Detergent and Soda Ash solution to the dye pot and stir well.

- Place wetted out fibers to the dye pot and slowly bring to 180F, rotating the fabric gently. Hold at 180F for 30 minutes.

- Carefully remove the fibers and rinse in cool water. Wring out excess water from the fibers and proceed to next step, Mordanting.

STEP 2: MORDANTING

Cellulose Fibers - Aluminum Acetate Followed by a Chalk Bath

MOST IMPORTANT STEP TO FOLLOW PRECISELY

The goal is to have enough mordant for dye to bond but, too much can be harmful to the fibers. For lighter shades it is NOT recommended to lighten up on mordant but to adjust the amount of dye used in the dyeing process.

Materials: Heat Source, Large Stainless-Steel Pot, 2 – 5-Gallon Buckets, 2 - Non-reactive mixing bowls, and a whisk.

Aluminum Acetate - 10% weight of the fabric

Chalk - Calcium Carbonate - 5% weight of the fabric

- You will want to wear protective equipment during this process. Put Aluminum Acetate in non-reactive bowl with a little cool water. Slowly add boiling water and whisk until dissolved into a solution.

- Fill the dye pot with hot water and stir in Aluminum Acetate solution.

- Add the wet, laundered fibers into the pot, stir and press out air bubbles that may be trapped in the fabric folds.

- Let sit for 45 minutes, rotating fibers occasionally.

- In the meantime, prepare a Chalk Bath by putting Calcium Carbonate in second non-reactive bowl with little cool water. Slowly add boiling water and whisk until dissolved into a solution. Once dissolved, add solution to the 5-gallon bucket designated for Chalk Bath. Fill with just enough hot water to cover fibers and stir.

- Remove fibers from Aluminum Acetate and put directly into the Chalk Bath for 15-30 minutes.

- Remove fibers from Chalk Bath, rinse lightly, and proceed to dyeing.

Note: Aluminum Acetate Solution can be used again but assume that ½ of the Aluminum Acetate has been transferred to the previously submerged fibers. This Mordant can be used at least 2 more times but will need to be reheated, or “recharged.” If there are flakes or cloudiness in your mordant, it is time to discard. Chalk Bath can also be reused at least 2 more times, just stir well before submerging fibers. Store your Aluminum Acetate and Chalk Baths in well-sealed 5-gallon buckets.

Discarding: You will want to neutralize your Aluminum Acetate bath with Soda Ash before pouring down the drain. Your Chalk Bath can go right down the drain with nothing added.

STEP 3: DYEING

Botanical Dyes and Color Manipulation

Materials: Water, Thermometer, Heat source, Non-reactive bowl, whisk, Dye Extract, 1-2 pots (second pot is for a Stop Bath if you want to finish process in hot water, without dye extract. Stopping when the color you want is achieved but still has processing time to go.)

- Put dye in non-reactive bowl, make a paste using warm water, dye extract, and whisk. Gradually add boiling water and stir until dissolved. Some extracts can get sticky during this process. You can let these dyes sit out for several hours or overnight to improve mixture/solution.

- Add plenty of warm water and botanical dye solution to dye pot that is large enough for submerging the fibers. Cellulose fibers have the tendency to float. There needs to be plenty of space for the fibers to move freely, so they can absorb an equal concentration of dye

- Add wet, mordanted fibers to the dye pot, stirring frequently to ensure even dyeing, and slowly heat to a simmer (45 min – 1 hr).

- Once desired temperature is reached, maintain the temperature for 30 – 60 minutes or until desired color is reached, frequently stirring gently.

- If Stop Bath is required, prepare ahead of time a secondary pot of water heated to a similar temperature.

- Once desired color is reached, move fabric over to Stop Bath to complete the total hour-long heated bath. This allows the dye to thoroughly penetrate the fabric. Note: colors will appear darker when wet.

- Optional color modifier: Iron Bath

- Allow fibers to cool to room temperature in the pot after heated bath is completed.

- Rinse thoroughly. Ideally you will first rinse in sink until water runs clear, then you can run fabrics through a rinse cycle in your washer if desired. You may now dry fabrics for use.